3D DETAIL SCANNING

WE ALSO TAKE CARE OF SCANNING OBJECTS OF SMALLER SIZES

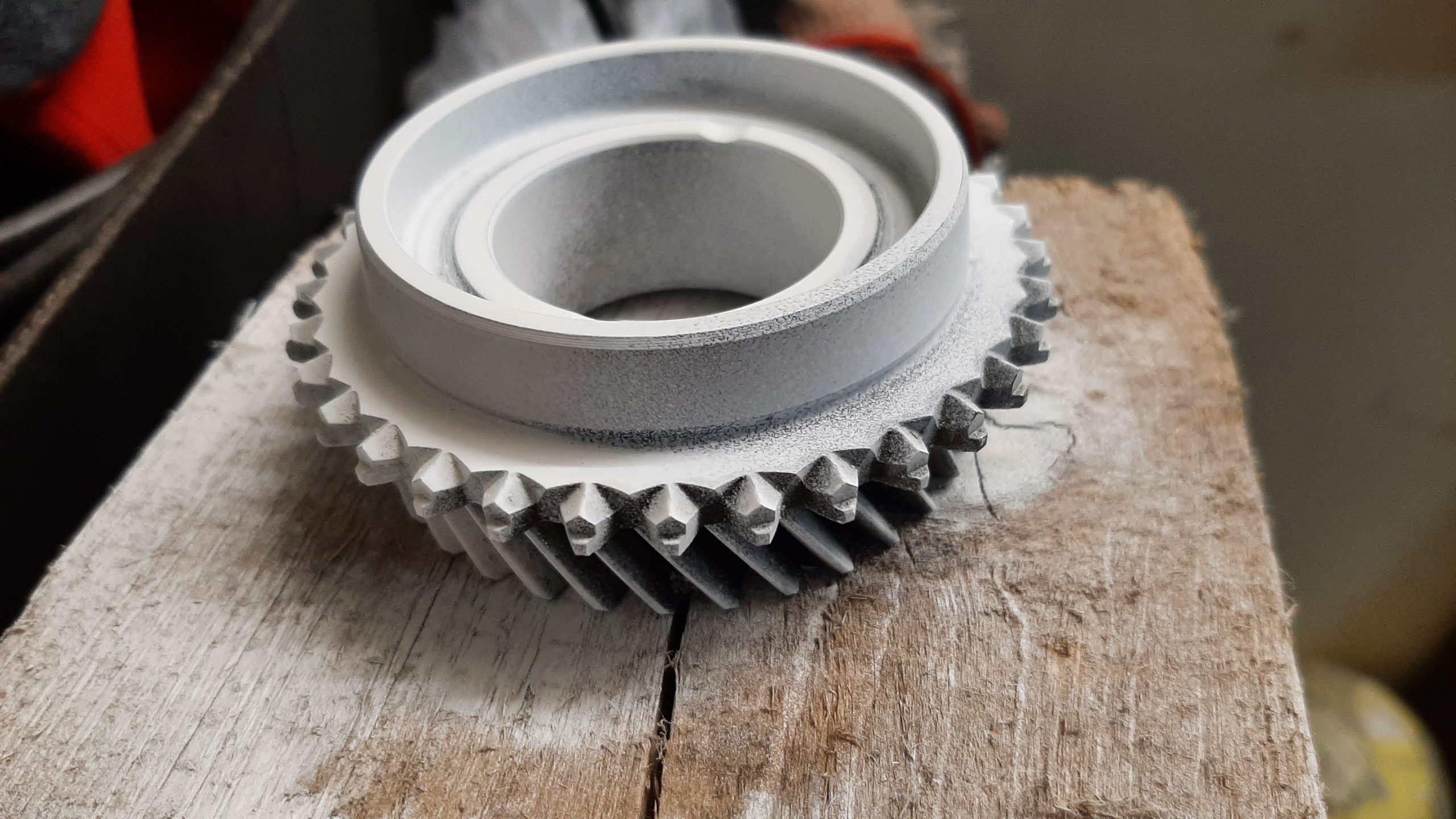

The use of 3D scanning meets the challenges of Industry 4.0 in the area of

area of reverse engineering and quality control – it provides, among other things, the ability to digitize

objects and non-contact inspection of their shape.

Lack of technical documentation needed to reproduce an object?

3D scanning produces a model consisting of a grid of triangles, which can then be

reconstructed in CAD software and re-manufactured, or make previously

needed modifications.

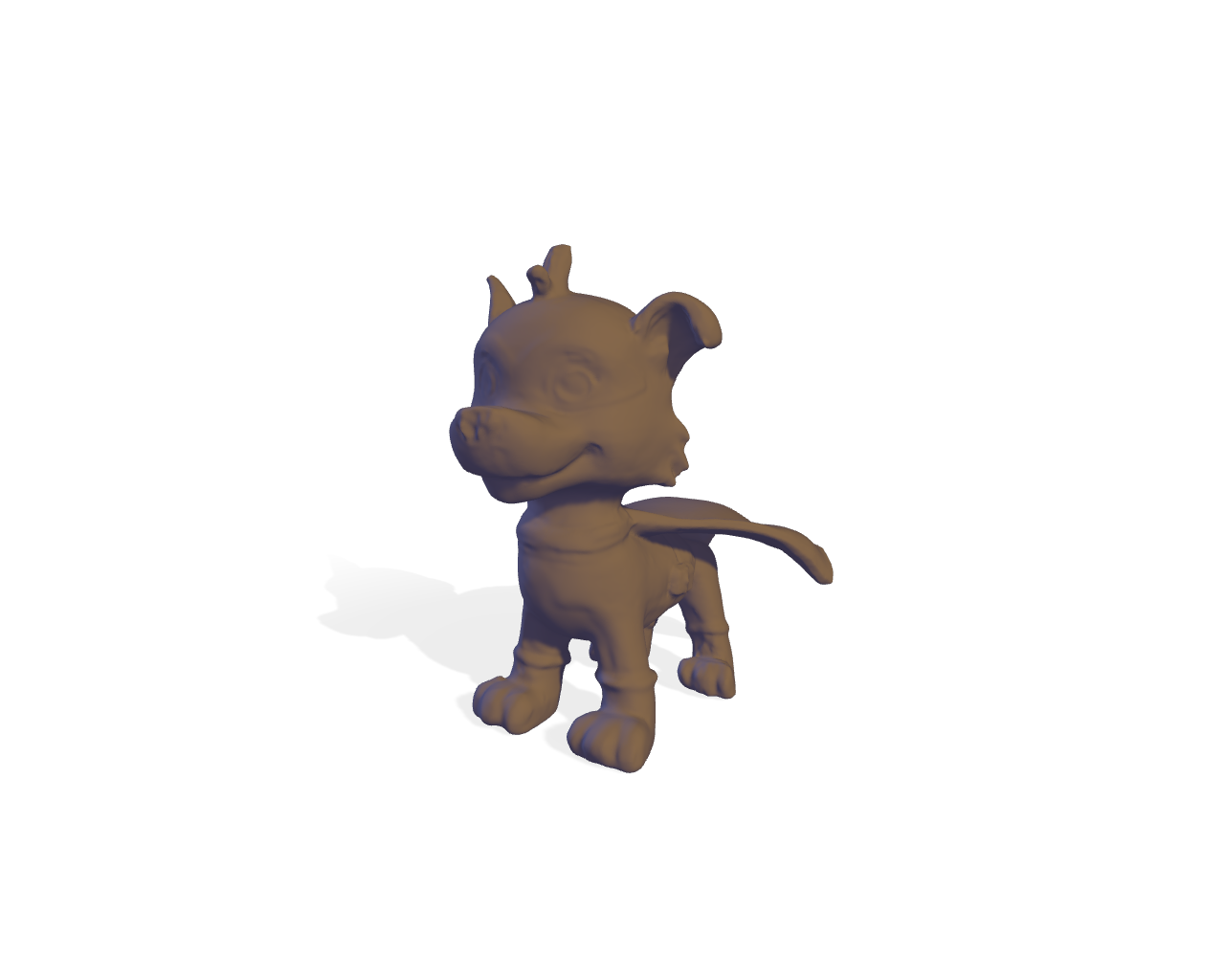

The applications of 3D scanning do not end with industry – it is successfully used

also in museums, for archiving and digitizing artifacts, which can then be

reconstructed using 3D printing and used for reconstruction and

educational purposes.

- 3D models in STL, OBJ, PLY, STEP formats

- Inspection of dimensional deviations

- Reverse engineering

- Digitization and archiving

- High accuracy – up to 0.1% of the object size (up to 0.06 mm)

- Single scan size up to 500 mm

- Object safety thanks to non-contact measurements

WE ALSO TAKE CARE OF SCANNING OBJECTS OF SMALLER SIZES

The use of 3D scanning meets the challenges of Industry 4.0 in

in the area of reverse engineering and quality control – it gives, among others possibility of digitization

objects and non-contact control of their shape.

Lack of technical documentation needed to restore the item?

With 3D scanning, you get a model consisting of a mesh of triangles that you can then

recreate in CAD software and re-produce or introduce earlier

needed modifications.

The applications of 3D scanning do not end with the industry – they are successfully applied

also in museology, with the archiving and digitization of exhibits, which can then be

reproduce using 3D printing and use for reconstruction purposes, and

educational.

- 3D models in STL, OBJ, PLY, STEP formats

- Inspection of dimensional deviations

- Reverse engineering

- Digitization and archiving

- High accuracy – up to 0.1% of the object size (up to 0.06 mm)

- Single scan size up to 500 mm

- Object safety thanks to non-contact measurements